21 European Conference

The Latest Technologies in Refrigeration, Air Conditioning and Heat Pumps

Refrigerants, Cold Chain, Environment, Energy, Training, Certification, Legislation, Standards, Safety

We thank the event’s Sponsors:

ARNEG GROUP

Arneg Group is an international leader in the design, manufacture and installation of complete equipment for the retail sector. With a widespread global presence, the group operates 21 production plants, 15 commercial and service companies, and 6 representative offices, covering Europe, the Americas, Asia, Africa, and Oceania.

Our range includes refrigerated counters and towers, hot cases, vertical and semi-vertical multi-deck cabinets, open and closed islands, wall counters, roll-in cabinets and rear service cabinets. A choice of built-in and remote refrigeration systems allows Arneg solutions to meet the needs of stores of all kinds.

CASTEL

Sustainability

La sostenibilità è un atto di responsabilità che spetta ad ognuno. Castel risponde sviluppando prodotti avanzati per sistemi a C02 e soluzioni tecnologiche mirate per ridurre l’impatto ambientale, in modo diretto e indiretto.

Technology

Refrigerazione e condizionamento dell’aria evolvono rapidamente, oggi più che in passato è fondamentale essere dinamici e competitivi. Per questo Castel è focalizzata sullo sviluppo di prodotti sempre più performanti, per affiancarti in nuove applicazioni e ambienti di utilizzo.

Affinity

Castel è sempre presente e connessa alle tue esigenze: i tuoi progetti diventano i nostri e ti affianchiamo passo dopo passo per realizzare insieme impianti sempre più efficienti, affidabili e duraturi.

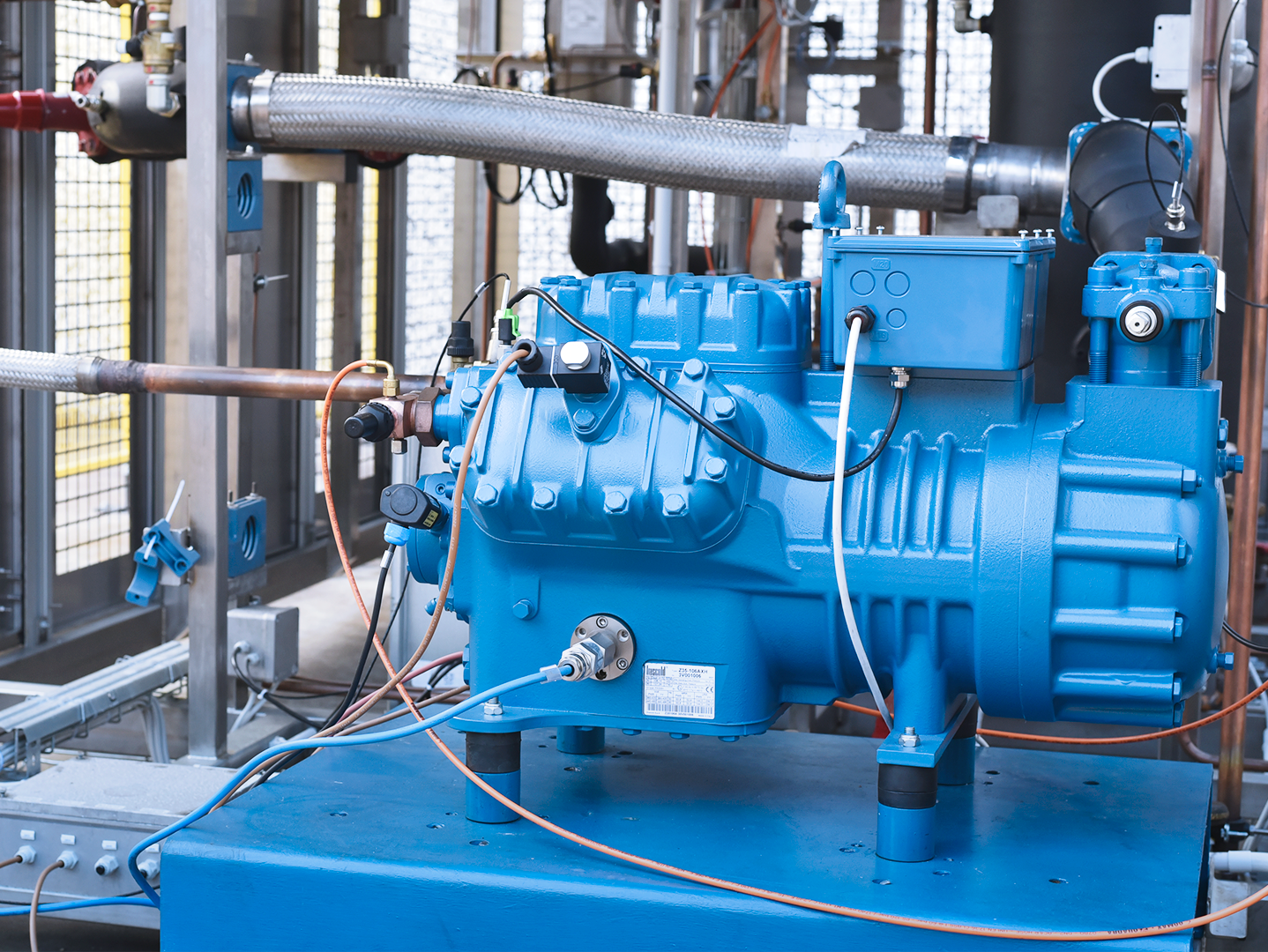

FRASCOLD

ATEX-certified solutions for a sustainable future

In a context of increasing focus on decarbonisation, Frascold is promoting the energy transition with a complete series of ATEX-certified reciprocating compressors. Designed for heat pumps destined for the industrial and residential sectors, in the latter they play a key role in medium/low temperature applications, with water temperatures up to 60°C.

In this scenario, semi-hermetic compressors prove to be a reliable and proven solution, proving to be the ideal choice for the design of heat pumps and chillers with propane, characterised by a heating or cooling capacity of 50 to 200 kW. Frascold’s ATEX reciprocating series has a volumetric flow rate of 4 to 240 m³/h and electric power ratings from 0.5 to 80 HP. These compressors can also be used in cascade systems or, alternatively, using waste heat to power the entire system, favouring a higher efficiency and circularity of resources.

The choice of the ideal refrigeration fluid for each application is the result of an appropriate balance among several factors, such as efficiency, safety, easy utilisation, sustainability, performance, costs and the availability of the gas in the market, in addition to its suitability for the specific application. The F-gas regulation, the Protocol of Kigali, as well as the standards adopted at domestic level are encouraging the industry towards an always more encompassing adoption of refrigeration fluids with low GWP – Global Warming Potential. In this sense, Frascold is acting in this direction by supporting investments in Research and Development with the purpose of creating added value for the Customers.

Co-organized by:

UNEP: United Nations Environment Programme, the branch of the UN which provides leadership and encourages partnerships in caring for the environment.

CSG: Centro Studi Galileo is the most renowned training centre in Italy and one of the leading in Europe and around the world for education and information in the sector of refrigeration, air conditioning and renewable energies.

IIR: International Institute of Refrigeration is a scientific and technical intergovernmental organization enabling the pooling of scientific and industrial know-how in all refrigeration fields on a worldwide scale.

ATF: Associazione dei Tecnici italiani del Freddo – Italian Association of Refrigeration Technicians, together with CSG, ATF has the target of developing renewable energies and the GND.

AREA: Air conditioning and Refrigeration European Association, the European association of refrigeration, air conditioning and heat pump (RACHP) contractors. Established in 1989, AREA voices the interests of 25 national associations from 21 countries.

REI: European Energy Centre, founded and based in the United Kingdom. The E.E.C. is the answer to the lack of highly skilled and qualified technicians in the renewable energy sector both in Europe and in developing countries.